Carbonaceous Nanoparticles

Formation of carbonaceous aerosols by combustion is critical in synthesis of functional nanomaterials but also has high impact on human health and the environment. For example, carbon black, the largest flame-made nanomaterial by value and volume (a $13B industry), is a major component in tires, inks, and batteries, while high value ($1’000/g) carbon-coated cobalt nanoparticles are used as magnetic biofluids (Kelesidis et al., PROCI, 2017). On the other hand, soot - a material very similar to carbon black - is an air pollutant.

Our understanding of carbonaceous nanoparticle formation in flames has advanced from an empirical description to an age of quantitative modeling for, at least, some nanoparticle properties. At the same time, very little is known about critical particle formation steps like nucleation (Kholghy et al., PCCP, 2018), surface growth (Kelesidis et al., Carbon, 2017), oxidation (Sediako et al., PROCI, 2017) and condensation (Kelesidis et al., Langmuir, 2018). This lack of understanding hinders the design of combustion and after-treatment processes for minimal, if not zero, emissions of soot, as well as the systematic scale-up and exploration of the properties of flame-made nanomaterials. Also, at a time when society is alarmed about climate change, still soot optical properties are calculated by Mie theory for spheres neglecting the fractal-like morphology of soot! This impedes accurate estimation of the environmental impact of soot as quantified by the radiative forcing resulting on more than 90% uncertainty, as well as soot characterization by optical diagnostics for selective detection with fire sensors that is responsible for false alarms costing £1B/y in UK alone.

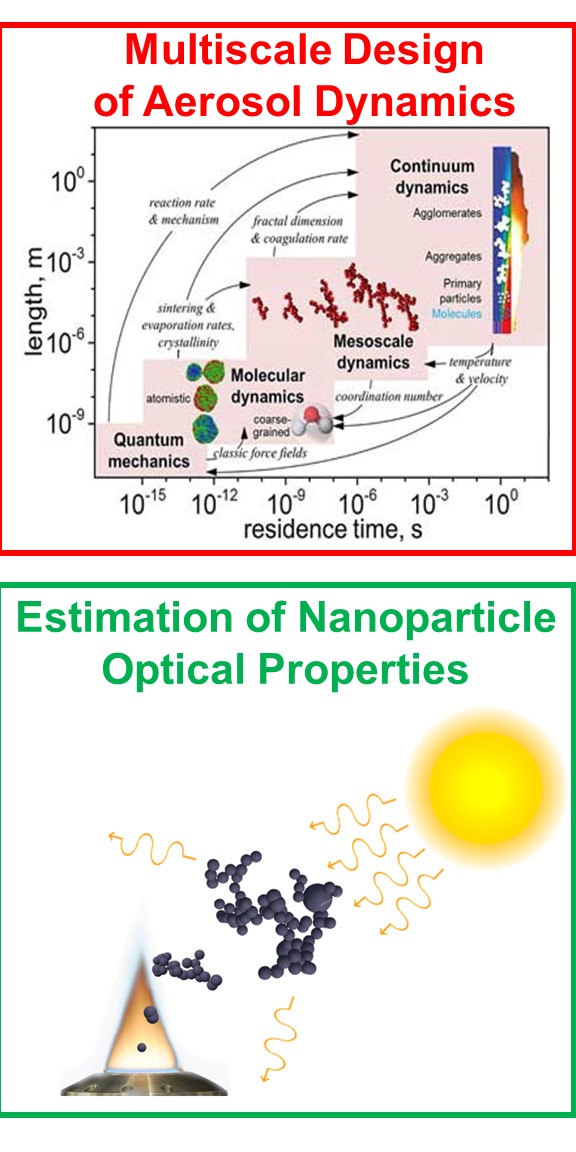

Here in PTL, we produce flame made carbonaceous nanoparticles and characterize their morphology, composition and optical properties. We then develop advanced multi-scale algorithms to predict particle morphology (Kelesidis et al., Carbon, 2017), composition (Kholghy et al., Carbon, 2016) and optical properties (Kelesidis et al., PROCI, 2018) and benchmark them with experiments. Finally, by using these algorithms we obtain critical engineering and scientific relations needed by industry or the scientific community.